The propeller is a rotating airfoil which produces thrust by creating a positive dynamic pressure, usually on the engine side. Some exceptions include the Piaggio Avanti, shown below which uses propellers mounted in what’s often referred to as the pusher configuration.

When a propeller rotates, the tips travel at a greater speed than the hub. To compensate for the greater speed at the tips, the blades are twisted slightly. The propeller blade angles decrease from the hub to the tips with the greatest angle of incidence, or highest pitch, at the hub and the smallest at the tip. This produces a relatively uniform angle of attack (uniform lift) along the blade’s length in cruise flight.

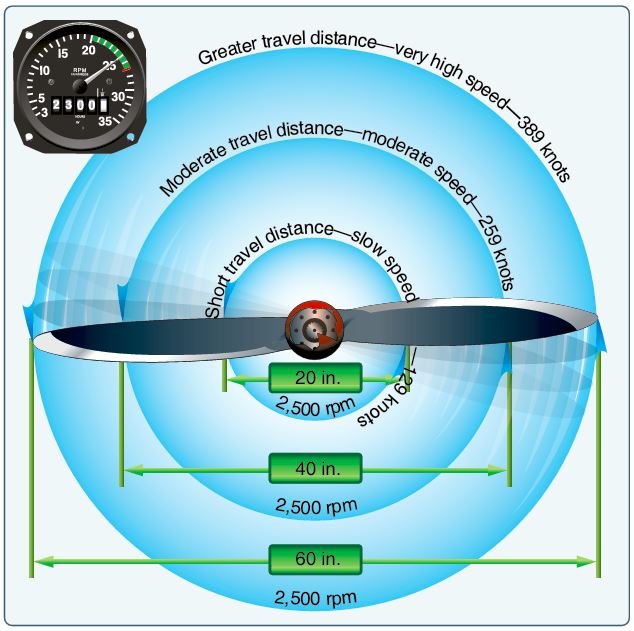

No propeller is 100% efficient. There is always some loss of power when converting engine output into thrust. This loss is primarily due to propeller slippage. A propeller’s efficiency is the ratio of thrust horsepower (propeller output) to brake horsepower (engine output). A fixed propeller will have a peak (best) efficiency at only one combination of airspeed and RPM.

A constant-speed (controllable-pitch) propeller allows the pilot to select the most efficient propeller blade angle for each phase of flight. In this system, the throttle controls the power output as registered on the manifold pressure gauge, and the propeller control regulates the engine RPM (propeller RPM). The pitch angle of the blades is changed by governor regulated oil pressure which keeps engine speed at a constant selected RPM. A constant-speed propeller allows the pilot to select a small propeller blade angle (flat pitch) and high RPM to develop maximum power and thrust for takeoff.

To reduce the engine output to climb power after takeoff, a pilot should decrease the manifold pressure. The RPM is decreased by increasing the propeller blade angle. When the throttle is advanced (increased) during cruise, the propeller pitch angle will automatically increase to allow engine RPM to remain the same. A pilot should avoid a high manifold pressure setting with low RPM on engines equipped with a constant-speed propeller to prevent placing undue stress on engine components. To avoid high manifold pressure combined with low RPM, the manifold pressure should be reduced before reducing RPM when decreasing power settings, and the RPM increased before increasing the manifold pressure when increasing power settings.

Let’s take a look at these three sample knowledge test questions and see if we can answer them given the information from Monday and todays posts.

1. Which statement best describes the operating principle of a constant-speed propeller?

A—As throttle setting is changed by the pilot, the prop governor causes pitch angle of the propeller blades to remain unchanged.

B—A high blade angle, or increased pitch, reduces the propeller drag and allows more engine power for takeoffs.

C—The propeller control regulates the engine RPM and in turn the propeller RPM.

2. Propeller efficiency is the

A—ratio of thrust horsepower to brake horsepower.

B—actual distance a propeller advances in one revolution.

C—ratio of geometric pitch to effective pitch.

3. A fixed-pitch propeller is designed for best efficiency only at a given combination of

A—altitude and RPM.

B—airspeed and RPM.

C—airspeed and altitude.

Answers in the comments section.