You don’t have to be a mechanic to be a safe pilot, but a knowledge of how your engine works and what the engine instruments are telling you will make it easier to give your engine tender loving care and get long, reliable service from it. Today we’ll cover your airplane’s ignition system, with a post taken from The Complete Private Pilot by Bob Gardner.

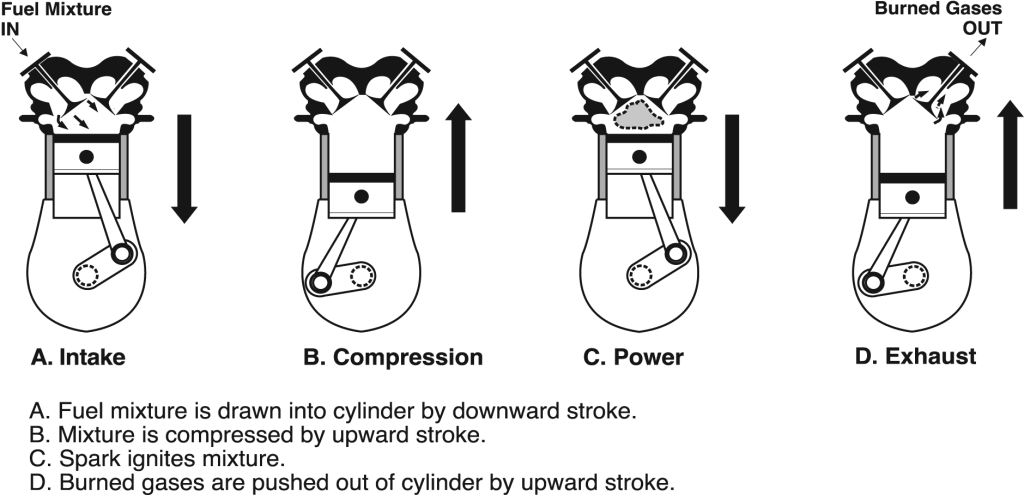

There are many similarities between an automobile engine and an airplane engine. Both are internal combustion engines, both use spark plugs, and both use some type of fuel metering system related to throttle position. An aircraft is a four-cycle engine: Figure 1 illustrates the four cycles. The fuelair mixture is drawn into the cylinder as the piston moves downward on the intake stroke; as the piston moves upward with the valves closed, the mixture is compressed during the compression stroke. The burning of the fuel-air mixture after ignition drives the piston downward during the power stroke, and as the piston rises again with the exhaust valve open the exhaust stroke ends the four stroke cycle. Because your aircraft engine has four or more cylinders, each igniting at a different time, there is always one piston on a power stroke, and the process is continuous.

Your gas-powered airplane engine uses a magneto as the source of ignition. Magneto may not be a familiar term to you, but your gas lawnmower, chain saw, or outboard motor all use magnetos. A magneto is a self-contained source of electrical impulses, using the physical motion of a coil and a fixed magnetic field to develop ignition voltage. To start the engine, you provide that physical motion by pulling a cord on your lawnmower, chain saw, or outboard. The starter motor does the job in the airplane, rotating the engine until the magneto-developed spark ignites the mixture. You have probably seen older airplanes without electrical systems (and newer airplanes with starter problems) being started manually—rotating the propeller by hand (“propping”) causes the magneto to generate a voltage which goes to the spark plug to ignite the fuel/air mixture. Hand-propping an airplane is a hazardous undertaking which requires an experienced and knowledgeable person both in the cockpit and at the propeller. Once an airplane engine is started, the magnetos provide continuous ignition on their own—the airplane’s electrical system and the starter motor have done their jobs. The master switch plays no further role in engine operation.

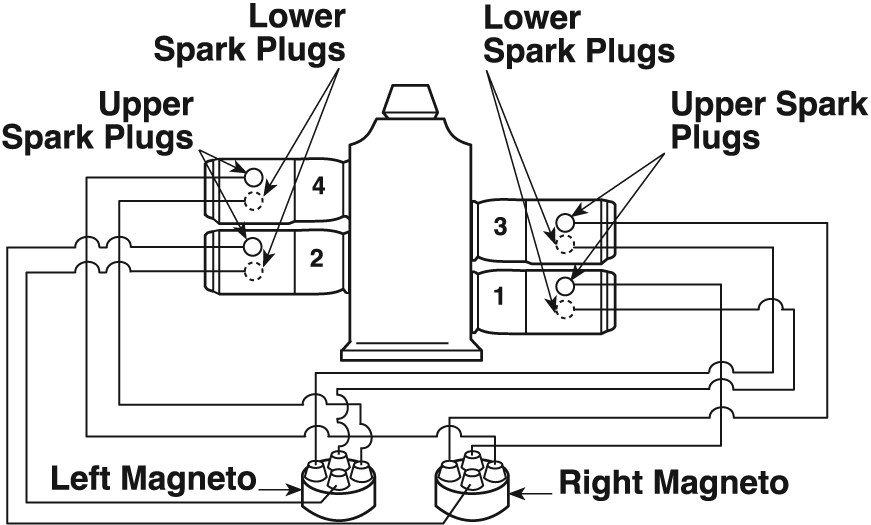

Each cylinder in your airplane engine has two spark plugs, each fired by a different magneto (see Figure 2). This has two advantages: better combustion efficiency, and safety. The engine will run on either magneto if one should develop a problem. Magnetos are totally independent of the aircraft electrical system.

When you turn the ignition off, with a key or with switches, you are connecting the electrical output of the magneto to the metal block of the engine where it is shorted to electrical ground and cannot fire the spark plugs. This “shorting out” is done through a wire called a P-lead, and if a P-lead is broken its associated magneto can fire the spark plugs even with the ignition in the OFF position. For this reason, you should treat all propellers with respect—moving the propeller might cause a magneto to start the engine unexpectedly if a P-lead has broken. During the preflight check of the airplane and its systems you will run the engine on each magneto separately. The ignition switch is marked OFF-LEFT-RIGHT-BOTH, if there is a start button, and OFF-L-R-BOTH-START if there is not (the START position is spring-loaded to return to the BOTH position when finger pressure is removed). In the OFF position, the P-leads of both magnetos are grounded; in the LEFT position, the right magneto is grounded and you are checking the operation of the left magneto. In the RIGHT position, then, the P-lead of the left magneto is grounded, and in the BOTH position, both magnetos are capable of delivering a spark.

As you cut the ignition sources in half you will lose some power, reflected as a drop in revolutions per minute (rpm). If no drop occurs when one magneto is shut off, that magneto probably has a broken P-lead, and the flight should be delayed until a mechanic checks it. Some authorities recommend checking for a broken P-lead just before shutting the engine down after a flight, by turning the ignition switch to its “OFF” position momentarily while at idle power; if the engine continues to run, there is probably a broken P-lead.

You should check your engine’s magnetos each time you are in the runup area preparing for takeoff. Magnetos can develop faults that are not readily detectable in cruising flight but which might rob the engine of the power required for takeoff.

We’ll have more on aircraft engines from our CFI on Thursday.